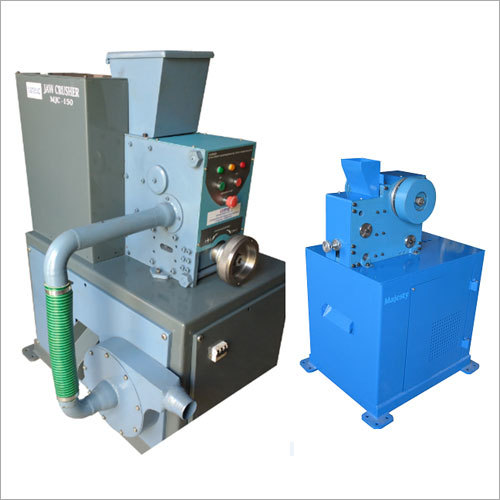

Lab Jaw Crusher

Lab Jaw Crusher Specification

- Rotation

- Through pulley drive

- Model

- Lab Jaw Crusher

- Product Type

- Jaw Crusher

- General Use

- Laboratory crushing, sample preparation, material reduction

- Material

- Mild Steel, Cast Iron

- Type

- Bench-top, Single Toggle

- Capacity

- 150 kg/hr (approx.)

- Weight (kg)

- Approx. 150 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No

- Control System

- Manual

- Floor Space

- Approx. 600 mm x 900 mm

- Spindle Speed

- 250 - 400 RPM

- Power

- 2 HP

- Voltage

- 220 V, 50 Hz

- Dimension (L*W*H)

- 1000 mm x 750 mm x 900 mm

- Feature

- Easy operation, robust construction, adjustable jaw gap

- Color

- Blue/White (as pictured)

Lab Jaw Crusher Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 2 Days

About Lab Jaw Crusher

Jaw Crusher is a compression type industrial machine which utilizes the vibratory motion generated by the hydraulic unit by moving the movable jaw against the fixed one to crush hard substances to reduce the size of the elements entered inside the hopper. It is designed and developed as per the industrial standards by using premium quality of materials that results in sturdy construction and longer service life. Jaw Crusher runs on the alternating electric voltage which gives power to the motor installed within the system to move the movable parts for the crushing application. It is also provided with a flywheel to reduce the fluctuations in the mechanical cycle.

Efficient Sample Preparation

This bench-top Lab Jaw Crusher streamlines the sample preparation process with its compression crushing mechanism, allowing rapid material reduction for laboratories and small-scale testing facilities. The adjustable jaw gap accommodates varying discharge needs, making it ideal for fine-tuning sample sizes before extensive analysis.

Robust Construction for Long-term Use

Built with high-quality mild steel and cast iron, the crusher is engineered for durability and resilience in demanding environments. The manganese steel jaw plates further enhance wear resistance, ensuring longevity even with frequent, heavy-duty usage.

Safety-First Design

Safety remains paramount; the unit comes with a comprehensive cover over all moving parts, protecting the operator during operation. This feature, combined with manual controls, keeps risks minimal without compromising on productivity or access.

FAQs of Lab Jaw Crusher:

Q: How does the adjustable discharge size benefit laboratory applications?

A: The adjustable discharge size (from 6 mm to 15 mm) enables precise control over sample output, which is essential for obtaining the required granularity for various testing and analysis procedures in laboratory settings.Q: What process does the Lab Jaw Crusher use to break down materials?

A: This model employs a compression mechanism with single toggle action, where materials are crushed between two manganese steel jaw plates, making it suitable for reducing hard or brittle samples found in mining, metallurgy, or construction.Q: Where can this jaw crusher be effectively utilized?

A: The Lab Jaw Crusher is ideal for laboratory sample preparation in mining, metallurgy, construction, and chemical industries. Its compact, stationary design makes it suitable for both educational institutions and industrial research labs.Q: When is it recommended to adjust the jaw gap?

A: Adjust the jaw gap whenever you need to produce a different output sizewhether for initial coarse reduction or finer sample particle mandates required for targeted testing procedures.Q: What are the safety features included with this model?

A: The unit is fitted with a full safety cover over all moving parts, significantly reducing accidental contact and ensuring safe operation during crushing tasks.Q: How is the crusher maintained for optimal performance?

A: Routine lubrication using its integrated grease system, along with periodic inspection of jaw plates and fasteners, helps sustain effective crushing and prolongs the service life of the equipment.Q: What are the key advantages of using this jaw crusher for material reduction?

A: The primary benefits include high processing capacity (up to 150 kg/hr), easy manual adjustments for varied discharge sizes, robust construction for long-term reliability, and secure safety features for operator protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Jaw Crusher Category

Laboratory Jaw Crusher

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : High Performance, ECO Friendly, Low Noise, High Efficiency

General Use : Industrial

Product Type : Jaw Crusher

Material : Cast Iron

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free